●Auto compensation balanced double parallel gate valve is a product with new structure, which has small open-and-close moment, high speed, little vibration,long performance life and reliable operation,It is mainly applied to cut-off or discharge of gas and liquid delivery pipelines.

The structural features include:

●A sealing structure consists of two parallel shutters and a wedge-tightening device it is taken to replace the traditional wedg eshaped gate valve structure;

●The components of valve sealing mechanism are separated so the sealing can retain when transmuting caused by the tem perature changes,and will not jam where swelling in high temperature;

●The sealing surface of the valve adopts abrasion-resistant and anti-corrosive materials which can lengthen the performance life of the valve;

●In high temperature or pressure,the disc on inlet side can be designed in pressure relief style which can avoid abnormal pressure rising in cavity caused by temperature changes,thus to ensure used safety.

●The valve adopts full-shut structure which has good protection function and can be used in all weather.

| Serial models | FY(K)Z44WH(Y)、FY(K)Z544WH(Y)、FY(K)Z644WH(Y)、FY(K)Z744WH(Y)、FY(K)Z944WH(Y) | |||

| FY(K)Z64WH(Y)、FY(K)Z564WH(Y)、FY(K)Z664WH(Y)、FY(K)Z764WH(Y)、FY(K)Z964WH(Y) | ||||

| Pressure grade range | PN1.6~10.0MPa | Class150~600 | ||

| Drift diameter range | DN50~900mm | 2"~36" | ||

| Driving manner | Hand wheel driving | Gear driving, air-operating, hydrodynamic driving and electric driving | ||

| Scope of application | Class150~300 (PN1.6~4.0) |

Class400 (PN6.4) |

Class600 (PN10.0) |

4"~36" (DN100~900mm) |

| 2"~36" (DN50~900mm) |

2"~36" (DN50~900mm) |

2"~32" (DN50~800mm) |

||

Note: Our company can provide products at customres'request.

| Pressure | Testing pressure at constant temperature (Mpa) | Applicable temperature | Applicable medium | |||||

| The shell testing | The left sealing | Right sealing | Low pressure air tightness | Ordinary type | Antisulphur type | |||

| (MPa) Nominal rating pressure (PN) |

1.6 | 2.4 | 1.76 | 1.76 | 0.6 | -29~121℃ or upon the user requirement |

Petroleum, natural gas,water etc. non-corrosive media |

Petroleum,natural gas, water etc,containing H₂S, CO₂ corrosive media |

| 2.5 | 3.75 | 2.75 | 2.75 | 0.6 | ||||

| 4.0 | 6.0 | 4.4 | 4.4 | 0.6 | ||||

| 6.4 | 9.6 | 7.04 | 7.04 | 0.6 | ||||

| 10.0 | 15.0 | 11.0 | 11.0 | 0.6 | ||||

| (Lb) Pound grade (Class) |

150 | 3.0 | 2.2 | 2.2 | 0.6 | |||

| 300 | 7.5 | 5.5 | 5.5 | 0.6 | ||||

| 600 | 15.0 | 11.0 | 11.0 | 0.6 | ||||

Technical Specification

|

Design reference | GB | API | |

| Design standard | JB/T 5298 GB/T 19672 |

API 6D ASME B16.34 |

||

| Structural length | Flanged ends | GB/T 12221 GB/T 19672、JB/T 5298 |

API 6D ASME B16.10 |

|

| Welded connection | GB/T 15188.1 GB/T 19672 |

|||

| Flanged ends | GB/T 9113 JB/T 79 |

ASME B16.5 MSS SP44 |

||

| Butt-welding ends | GB/T 12224 | ASME B16.25 | ||

| Test & inspection | JB/T 9092 | API 6D API 598 |

||

Note: The sizes of valve connecting flange can be designed according to customers'requirement.

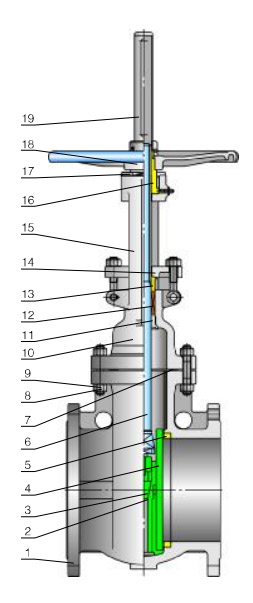

Major Parts Material Form

|

NO. | Accessory name | Material | |||

| Ordinary type | Antisulphur type | |||||

| GB | ASTM | GB | ASTM | |||

| 1 | Body | WCB | A216-WCB | WCB | A216-WCB | |

| 2 | Disc frame | WCB | A216-WCB | WCB | A216-WCB | |

| 3 | Wedge block | WCB+STL | A216-WCB+STL | WCB+STL | A216-WCB+STL | |

| 4 | Disc | 25+STL | A105+STL | 1Cr18Ni9+STL | A276-304+STL | |

| 5 | Seat | 25+STL | A105+STL | 1Cr18Ni9+STL | A276-304+STL | |

| 6 | Stem | 2Cr13 | A276-410 | 1Cr18Ni9 | A276-304 | |

| 7 | Gasket | Graphite+1Cr18Ni9 | Graphite+304 | Graphite+1Cr18Ni9 | Graphite+304 | |

| 8 | Stud | 35CrMoA | A193-B7 | 35CrMoA | A193-B7 | |

| 9 | Nut | 35 | A194-2H | 35 | A194-2H | |

| 10 | Bonnet | WCB | A216-WCB | WCB | A216-WCB | |

| 11 | Back seat | 1Cr13 | A276-410 | 1Cr18Ni9 | A276-304 | |

| 12 | Packing | Graphite | ||||

| 13 | Packing press-sleeve | 2Cr13 | A276-420 | 2Cr13 | A276-420 | |

| 14 | Packing gland | WCB | A276-WCB | WCB | A216-WCB | |

| 15 | Yoke | WCB | A216-WCB | WCB | A216-WCB | |

| 16 | Stem nut | ZQA19-4 | C95500 | ZQA19-4 | C95500 | |

| 17 | Gland | 25 | A105 | 25 | A105 | |

| 18 | Hand wheel | QT400-17 | A536-60-40-18 | QT400-17 | A536-60-40-18 | |

| 19 | Indicating cover | 25 | A105 | 25 | A105 | |

Notes: The major parts of the valves can be designed and selected according to actual work condition or customers' specific requirement.

Technical Specification

|

Design reference | GB | API | |

| Design standard | JB/T 5298 GB/T 19672 |

API 6D ASME B16.34 |

||

| Structural length | Flanged ends | GB/T 12221 GB/T 19672、JB/T 5298 |

API 6D ASME B16.10 |

|

| Welded connection | GB/T 15188.1 GB/T 19672 |

|||

| Flanged ends | GB/T 9113 JB/T 79 |

ASME B16.5 MSS SP44 |

||

| Butt-welding ends | GB/T 12224 | ASME B16.25 | ||

| Test & inspection | JB/T 9092 | API 6D API 598 |

||

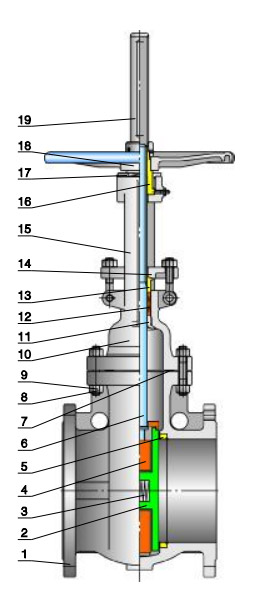

Major Parts Material Form

|

NO. | Accessory name | Material | |||

| Ordinary type | Antisulphur type | |||||

| GB | ASTM | GB | ASTM | |||

| 1 | Body | WCB | A216-WCB | WCB | A216-WCB | |

| 2 | Disc | 25+STL | A216-WCB | WCB | A216-WCB | |

| 3 | Spring | Inconel X-750 | ||||

| 4 | Disc frame | WCB | A216-WCB | WCB | A216-WCB | |

| 5 | Seat | 25+STL | A105+STL | 1Cr18Ni9+STL | A276-304+STL | |

| 6 | Stem | 2Cr13 | A276-410 | 1Cr18Ni9 | A276-304 | |

| 7 | Gasket | Graphite+1Cr18Ni9 | Graphite+304 | Graphite+1Cr18Ni9 | Graphite+304 | |

| 8 | Stud | 35CrMoA | A193-B7 | 35CrMoA | A193-B7 | |

| 9 | Nut | 35 | A194-2H | 35 | A194-2H | |

| 10 | Bonnet | WCB | A216-WCB | WCB | A216-WCB | |

| 11 | Back seat | 1Cr13 | A276-410 | 1Cr18Ni9 | A276-304 | |

| 12 | Packing | Graphite | ||||

| 13 | Packing press-sleeve | 2Cr13 | A276-420 | 2Cr13 | A276-420 | |

| 14 | Packing gland | WCB | A276-WCB | WCB | A216-WCB | |

| 15 | Yoke | WCB | A216-WCB | WCB | A216-WCB | |

| 16 | Stem nut | ZQA19-4 | C95500 | ZQA19-4 | C95500 | |

| 17 | Gland | 25 | A105 | 25 | A105 | |

| 18 | Hand wheel | QT400-17 | A536-60-40-18 | QT400-17 | A536-60-40-18 | |

| 19 | Indicating cover | 25 | A105 | 25 | A105 | |

Notes: The major parts of the valves can be designed and selected according to actual work condition or customers' specific requirement.

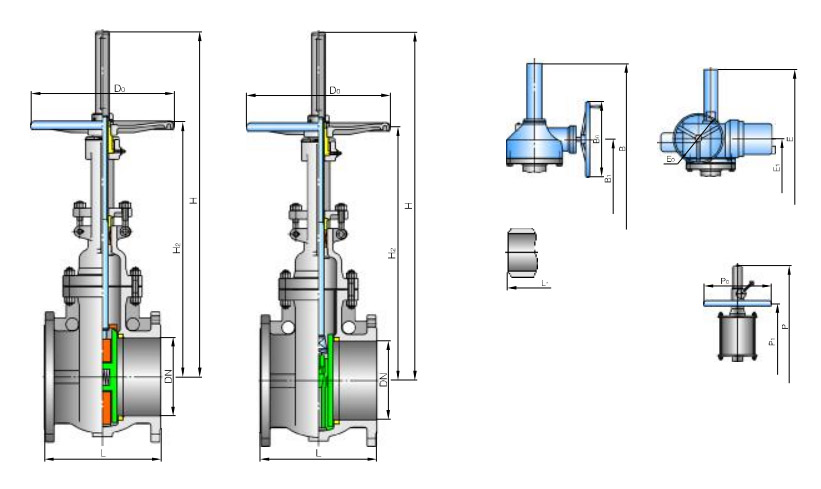

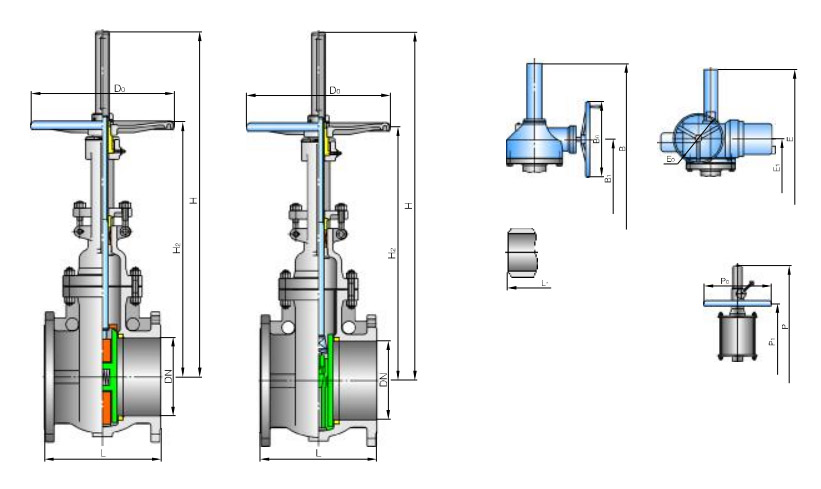

Main Size of Outside

Model: (K)Z5(6、9)4(6)4W(F、Y、D) PN4.0MPa PN5.0MPa API 6D Class300

| DN (mm) |

NPS (in) |

Flange | Butt welding | Hand-operated | Geared driving | Geared driving | Air-operating and Fluid driving | Electric driving device | Electric driving device | |||||||||

| L | ||||||||||||||||||

| GB | API | L₁ | H | H₂ | D₀ | B | B₁ | B₀ | P | P₁ | P₀ | E | E₂ | E₀ | ||||

| 50 | 2 | 250 | 178 | 216 | 475 | 360 | 250 | - | - | - | - | - | - | - | 690 | 572 | 200 | SMC-04 |

| 65 | 2¹/₂ | 280 | 190 | 241 | 535 | 425 | 300 | - | - | - | - | - | - | - | 747 | 637 | 200 | SMC-04 |

| 80 | 3 | 310 | 203 | 283 | 600 | 460 | 300 | - | - | - | - | 1075 | 820 | 250 | 812 | 672 | 200 | SMC-04 |

| 100 | 4 | 350 | 229 | 305 | 700 | 535 | 350 | - | - | - | - | 1240 | 945 | 250 | 960 | 795 | 508 | SMC-03 |

| 150 | 6 | 450 | 267 | 403 | 910 | 685 | 350 | - | - | - | - | 1400 | 1065 | 300 | 1170 | 945 | 508 | SMC-03 |

| 200 | 8 | 550 | 292 | 419 | 1095 | 815 | 350 | 1235 | 900 | 310 | BA-0 | 1595 | 1210 | 300 | 1355 | 1075 | 508 | SMC-03 |

| 250 | 10 | 650 | 330 | 457 | 1370 | 965 | 450 | 1510 | 1050 | 310 | BA-0 | 1800 | 1370 | 350 | 1630 | 1095 | 305 | SMC-00 |

| 300 | 12 | 750 | 356 | 502 | 1470 | 1100 | 500 | 1610 | 1185 | 310 | BA-0 | 2090 | 1590 | 350 | 1730 | 1230 | 305 | SMC-00 |

| 350 | 14 | 850 | 381 | 572 | 1730 | 1250 | 600 | 1890 | 1345 | 460 | BA-1 | 2420 | 1845 | 350 | 2020 | 1417 | 305 | SMC-00 |

| 400 | 16 | 950 | 406 | 610 | 1870 | 1375 | 650 | 2030 | 1470 | 460 | BA-1 | 2615 | 1995 | 400 | 2160 | 1532 | 305 | SMC-00 |

| 450 | 18 | 1050 | 432 | 660 | 2185 | 1485 | 700 | 2415 | 1625 | 460 | BA-2 | 2895 | 2205 | 500 | 2500 | 1651 | 305 | SMC-1 |

| 500 | 20 | 1150 | 457 | 711 | 2335 | 1575 | 800 | 2565 | 1715 | 460 | BA-2 | 3160 | 2405 | 600 | 2650 | 1741 | 305 | SMC-1 |

| 600 | 24 | 1350 | 508 | 813 | 2815 | 1995 | 1000 | 3045 | 2135 | 460 | BA-2 | 3885 | 2955 | 650 | 3130 | 2161 | 457 | SMC-2 |

| 700 | 28 | 1450 | 610 | 914 | - | - | - | - | - | - | - | 4065 | 3090 | 700 | 3630 | 2470 | 457 | SMC-2 |

| 800 | 32 | 1650 | 660 | 965 | - | - | - | - | - | - | - | - | - | - | 4135 | 2933 | 610 | SMC-3 |

| 900 | 36 | 1880 | 813 | 1016 | - | - | - | - | - | - | - | + | + | + | 4605 | 3260 | 610 | SMC-3 |

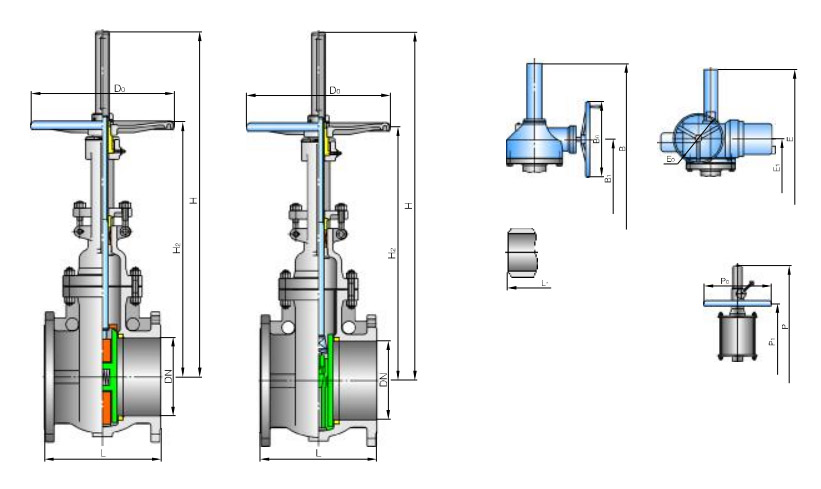

Main Size of Outside

Model: (K)Z5(6、9)4(6)4W(F、Y、D) PN1.6、2.5MPa PN2.0MPa API 6D Class150

| DN (mm) |

NPS (in) |

Flange | Butt welding | Hand-operated | Geared driving | Geared driving | Air-operating and Fluid driving | Electric driving device | Electric driving device | |||||||||

| L | ||||||||||||||||||

| GB | API | L₁ | H | H₂ | D₀ | B | B₁ | B₀ | P | P₁ | P₀ | E | E₁ | E₀ | ||||

| 50 | 2 | 250 | 216 | 216 | 475 | 360 | 250 | - | - | - | - | - | - | - | 690 | 572 | 200 | SMC-04 |

| 65 | 2¹/₂ | 280 | 241 | 241 | 535 | 425 | 300 | - | - | - | - | - | - | - | 747 | 637 | 200 | SMC-04 |

| 80 | 3 | 310 | 283 | 283 | 600 | 460 | 300 | - | - | - | - | 1075 | 820 | 250 | 860 | 720 | 500 | SMC-03 |

| 100 | 4 | 350 | 305 | 305 | 700 | 535 | 350 | - | - | - | - | 1240 | 945 | 250 | 960 | 795 | 500 | SMC-03 |

| 150 | 6 | 450 | 403 | 403 | 910 | 685 | 350 | - | - | - | - | 1400 | 1065 | 300 | 1170 | 945 | 500 | SMC-03 |

| 200 | 8 | 550 | 419 | 419 | 1095 | 815 | 350 | 1235 | 900 | 310 | BA-0 | 1595 | 1210 | 300 | 1355 | 945 | 305 | SMC-00 |

| 250 | 10 | 650 | 457 | 457 | 1370 | 965 | 450 | 1510 | 1050 | 310 | BA-0 | 1800 | 1370 | 350 | 1630 | 1095 | 305 | SMC-00 |

| 300 | 12 | 750 | 502 | 502 | 1470 | 1100 | 500 | 1610 | 1185 | 310 | BA-0 | 2090 | 1590 | 350 | 1760 | 1257 | 305 | SMC-0 |

| 350 | 14 | 850 | 762 | 762 | 1730 | 1250 | 600 | 1890 | 1345 | 460 | BA-1 | 2420 | 1845 | 350 | 2020 | 1407 | 305 | SMC-0 |

| 400 | 16 | 950 | 838 | 838 | 1870 | 1375 | 650 | 2030 | 1470 | 460 | BA-1 | 2615 | 1995 | 400 | 2185 | 1541 | 305 | SMC-1 |

| 450 | 18 | 1050 | 914 | 914 | 2185 | 1485 | 700 | 2415 | 1625 | 460 | BA-2 | 2895 | 2205 | 500 | 2500 | 1651 | 305 | SMC-1 |

| 500 | 20 | 1150 | 991 | 991 | 2335 | 1575 | 800 | 2565 | 1715 | 460 | BA-2 | 3160 | 2405 | 600 | 2695 | 1757 | 457 | SMC-2 |

| 600 | 24 | 1350 | 1143 | 1143 | 2815 | 1995 | 1000 | 3045 | 2135 | 460 | BA-2 | 3885 | 2955 | 650 | 3175 | 2177 | 457 | SMC-2 |

| 700 | 28 | 1450 | 1346 | 1346 | - | - | - | - | - | - | - | 4065 | 3090 | 700 | 3670 | 2606 | 610 | SMC-3 |

| 800 | 32 | 1650 | 1524 | 1524 | - | - | - | - | - | - | - | - | - | - | 4136 | 2933 | 610 | SMC-3 |

| 900 | 36 | 1880 | 1727 | 1727 | - | - | - | - | - | - | - | + | + | + | 4673 | 3317 | 610 | SMC-4 |

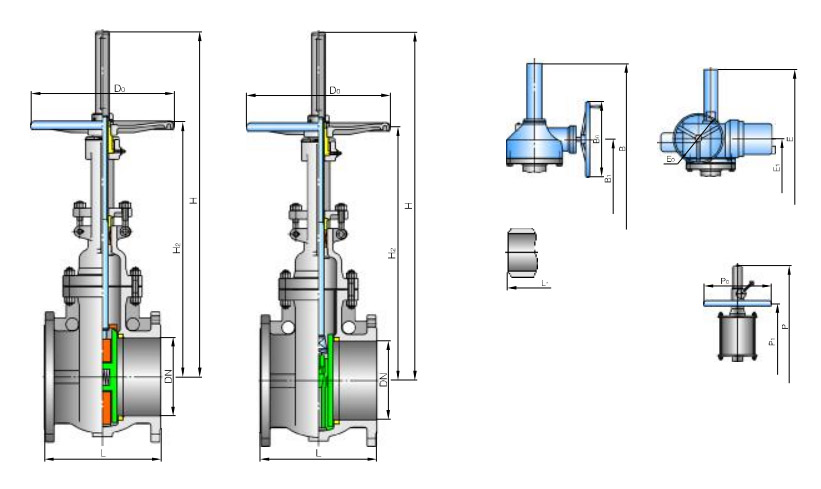

Main Size of Outside

Model: (K)Z5(6、9)4(6)4W(F、Y、D) PN6.4MPa

| DN (mm) |

NPS (in) |

Flange | Butt welding | Hand-operated | Geared driving | Geared driving | Air-operating and Fluid driving | Electric driving device | Electric driving device | ||||||||

| L | L₁ | H | H₂ | D₀ | B | B₁ | B₀ | P | P₁ | P₀ | E | E₁ | E₀ | ||||

| 50 | 2 | 250 | 292 | 499 | 378 | 250 | - | - | - | - | - | - | - | 723 | 601 | 200 | SMC-04 |

| 65 | 2¹/₂ | 280 | 330 | 562 | 446 | 300 | - | - | - | - | - | - | - | 785 | 670 | 200 | SMC-04 |

| 80 | 3 | 310 | 356 | 630 | 483 | 300 | - | - | - | - | 1130 | 861 | 250 | 902 | 756 | 508 | SMC-03 |

| 100 | 4 | 350 | 406 | 735 | 562 | 350 | - | - | - | - | 1302 | 992 | 250 | 1007 | 838 | 508 | SMC-03 |

| 150 | 6 | 450 | 495 | 956 | 720 | 350 | 1096 | 805 | 305 | BA-0 | 1470 | 1118 | 300 | 1216 | 848 | 305 | SMC-00 |

| 200 | 8 | 550 | 597 | 1150 | 856 | 400 | 1290 | 941 | 305 | BA-0 | 1675 | 1271 | 300 | 1440 | 1013 | 305 | SMC-0 |

| 250 | 10 | 650 | 673 | 1439 | 1013 | 500 | 1580 | 1098 | 305 | BA-0 | 1890 | 1440 | 350 | 1728 | 1170 | 305 | SMC-0 |

| 300 | 12 | 750 | 762 | 1545 | 1155 | 600 | 1705 | 1250 | 458 | BA-1 | 2195 | 1670 | 350 | 1833 | 1312 | 305 | SMC-0 |

| 350 | 14 | 850 | 826 | 1817 | 1313 | 650 | 1977 | 1408 | 458 | BA-1 | 2542 | 1937 | 350 | 2131 | 1480 | 305 | SMC-1 |

| 400 | 16 | 950 | 902 | 1965 | 1445 | 700 | 2125 | 1540 | 458 | BA-1 | 2746 | 2095 | 400 | 2278 | 1610 | 305 | SMC-1 |

| 450 | 18 | 1050 | 978 | 2295 | 1560 | 800 | 2525 | 1700 | 458 | BA-2 | 3040 | 2315 | 500 | 2655 | 1741 | 457 | SMC-2 |

| 500 | 20 | 1150 | 1054 | 2452 | 1655 | 1000 | 2682 | 1795 | 458 | BA-2 | 3318 | 2525 | 600 | 2812 | 1836 | 610 | SMC-3 |

| 600 | 24 | 1350 | 1232 | - | - | - | 3186 | 2235 | 458 | BA-2 | 4080 | 3103 | 650 | 3356 | 2413 | 610 | SMC-3 |

| 700 | 28 | 1450 | 1397 | - | - | - | - | - | - | - | 4268 | 3245 | 700 | 3902 | 2777 | 610 | SMC-4 |

| 800 | 32 | 1650 | 1651 | - | - | - | - | - | - | - | - | - | - | 4393 | 3121 | 610 | SMC-4 |

| 900 | 36 | 1880 | 1880 | - | - | - | - | - | - | - | - | - | - | 4863 | 3428 | 760 | SMC-5 |

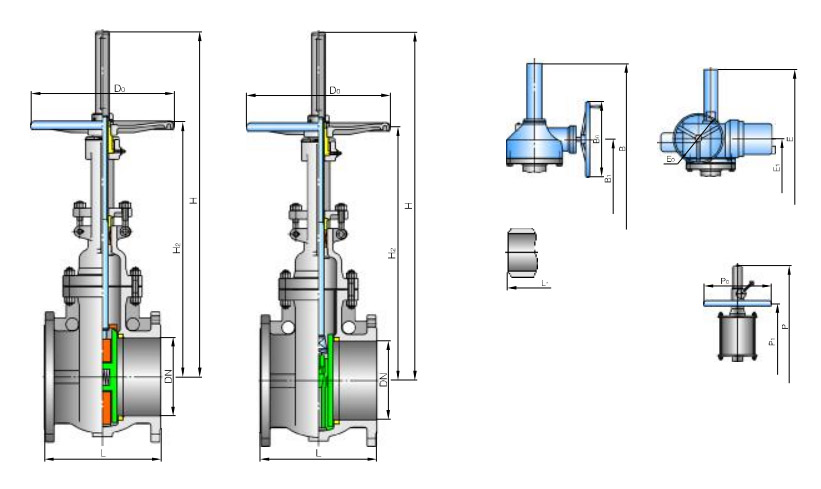

Main Size of Outside

Model: (K)Z5(6、9)4(6)4W(F、Y、D) API 6D Class400

| DN (mm) |

NPS (in) |

Flange | Butt welding | Hand-operated | Geared driving | Geared driving | Air-operating and Fluid driving | Electric driving device | Electric driving device | ||||||||

| L | L₁ | H | H₂ | D₀ | B | B₁ | B₀ | P | P₁ | P₀ | E | E₁ | E₀ | ||||

| 50 | 2 | 292 | 292 | 499 | 378 | 250 | - | - | - | - | - | - | - | 723 | 601 | 200 | SMC-04 |

| 65 | 2¹/₂ | 330 | 330 | 562 | 446 | 300 | - | - | - | - | - | - | - | 785 | 670 | 200 | SMC-04 |

| 80 | 3 | 356 | 356 | 630 | 483 | 300 | - | - | - | - | 1130 | 861 | 250 | 902 | 756 | 508 | SMC-03 |

| 100 | 4 | 406 | 406 | 735 | 562 | 350 | - | - | - | - | 1302 | 992 | 250 | 1007 | 838 | 508 | SMC-03 |

| 150 | 6 | 495 | 495 | 956 | 720 | 350 | 1096 | 805 | 305 | BA-0 | 1470 | 1118 | 300 | 1216 | 848 | 305 | SMC-00 |

| 200 | 8 | 597 | 597 | 1150 | 856 | 400 | 1290 | 941 | 305 | BA-0 | 1675 | 1271 | 300 | 1440 | 1013 | 305 | SMC-0 |

| 250 | 10 | 673 | 673 | 1439 | 1013 | 500 | 1580 | 1098 | 305 | BA-0 | 1890 | 1440 | 350 | 1728 | 1170 | 305 | SMC-0 |

| 300 | 12 | 762 | 762 | 1545 | 1155 | 600 | 1705 | 1250 | 458 | BA-1 | 2195 | 1670 | 350 | 1833 | 1312 | 305 | SMC-0 |

| 350 | 14 | 826 | 826 | 1817 | 1313 | 650 | 1977 | 1408 | 458 | BA-1 | 2542 | 1937 | 350 | 2131 | 1480 | 305 | SMC-1 |

| 400 | 16 | 902 | 902 | 1965 | 1445 | 700 | 2125 | 1540 | 458 | BA-1 | 2746 | 2095 | 400 | 2278 | 1610 | 305 | SMC-1 |

| 450 | 18 | 978 | 978 | 2295 | 1560 | 800 | 2525 | 1700 | 458 | BA-2 | 3040 | 2315 | 500 | 2655 | 1741 | 457 | SMC-2 |

| 500 | 20 | 1054 | 1054 | 2452 | 1655 | 1000 | 2682 | 1795 | 458 | BA-2 | 3318 | 2525 | 600 | 2812 | 1836 | 610 | SMC-3 |

| 600 | 24 | 1232 | 1232 | - | - | - | 3186 | 2235 | 458 | BA-2 | 4080 | 3103 | 650 | 3356 | 2413 | 610 | SMC-3 |

| 700 | 28 | 1397 | 1397 | - | - | - | - | - | - | - | 4268 | 3245 | 700 | 3902 | 2777 | 610 | SMC-4 |

| 800 | 32 | 1650 | 1650 | - | - | - | - | - | - | - | - | - | - | 4393 | 3121 | 610 | SMC-4 |

| 900 | 36 | 1880 | 1880 | - | - | - | - | - | - | - | - | - | - | 4863 | 3428 | 760 | SMC-5 |

Main Size of Outside

Model: (K)Z5(6、9)4(6)4W(F、Y、D) PN10.0Pa API 6D Class400

| DN (mm) |

NPS (in) |

Flange | Butt welding | Hand-operated | Geared driving | Geared driving | Air-operating and Fluid driving | Electric driving device | Electric driving device | ||||||||

| L | L₁ | H | H₂ | D₀ | B | B₁ | B₀ | P | P₁ | P₀ | E | E₁ | E₀ | ||||

| 50 | 2 | 292 | 292 | 499 | 378 | 300 | - | - | - | - | - | - | - | 723 | 600 | 200 | SMC-04 |

| 65 | 2¹/₂ | 330 | 330 | 562 | 446 | 350 | - | - | - | - | - | - | - | 821 | 705 | 508 | SMC-03 |

| 80 | 3 | 356 | 356 | 630 | 483 | 350 | - | - | - | - | 1130 | 861 | 250 | 890 | 742 | 508 | SMC-03 |

| 100 | 4 | 432 | 432 | 735 | 562 | 400 | - | - | - | - | 1302 | 992 | 250 | 995 | 690 | 305 | SMC-00 |

| 150 | 6 | 559 | 559 | 956 | 720 | 500 | 1096 | 805 | 305 | BA-0 | 1470 | 1118 | 300 | 1245 | 876 | 305 | SMC-0 |

| 200 | 8 | 660 | 660 | 1150 | 856 | 600 | 1290 | 941 | 305 | BA-0 | 1675 | 1271 | 300 | 1440 | 1013 | 305 | SMC-0 |

| 250 | 10 | 787 | 787 | 1439 | 1013 | 650 | 1580 | 1098 | 458 | BA-1 | 1890 | 1440 | 350 | 1753 | 1199 | 305 | SMC-1 |

| 300 | 12 | 838 | 838 | 1545 | 1155 | 700 | 1705 | 1250 | 458 | BA-1 | 2195 | 1670 | 350 | 1858 | 1321 | 305 | SMC-1 |

| 350 | 14 | 889 | 889 | 1817 | 1313 | 800 | 1977 | 1408 | 458 | BA-1 | 2542 | 1937 | 350 | 2177 | 1495 | 457 | SMC-2 |

| 400 | 16 | 991 | 991 | 1965 | 1445 | 1000 | 2125 | 1540 | 458 | BA-2 | 2746 | 2095 | 400 | 2365 | 1762 | 610 | SMC-3 |

| 450 | 18 | 1092 | 1092 | - | - | - | 2525 | 1700 | 458 | BA-2 | 3040 | 2315 | 500 | 2695 | 1877 | 610 | SMC-3 |

| 500 | 20 | 1194 | 1194 | - | - | - | 2682 | 1795 | 458 | BA-2 | 3318 | 2525 | 600 | 2922 | 2030 | 610 | SMC-4 |

| 600 | 24 | 1397 | 1397 | - | - | - | - | - | - | - | 4080 | 3103 | 650 | 3426 | 2470 | 610 | SMC-4 |

| 700 | 28 | 1549 | 1549 | - | - | - | - | - | - | - | 4268 | 3245 | 700 | 3983 | 2835 | 760 | SMC-5 |

| 800 | 32 | 1778 | 1778 | - | - | - | - | - | - | - | - | - | - | 4485 | 3186 | 760 | SMC-5 |

The increasing popularity of IoT devices has driven the demand for industrial valves. The integration of IoT sensors in industrial valves enables real-time monitorin...

A gate valve is an opening and closing component, and its movement direction is perpendicular to the fluid direction. A gate valve can only be fully opened and fully...

Ball valve, the opening and closing element (ball) is driven by the valve stem and rotates around the axis of the ball valve. It can also be used for fluid regulatio...