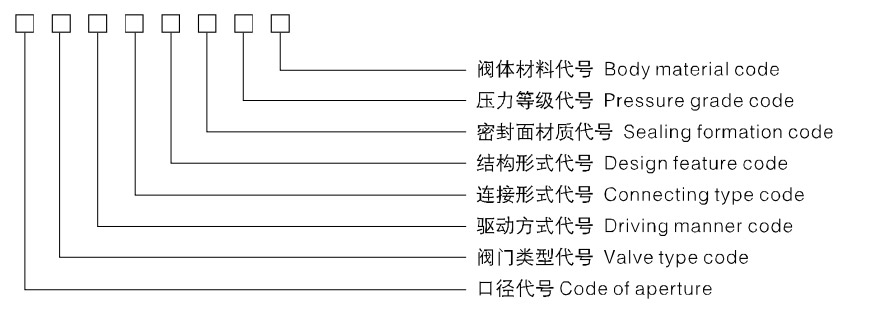

●Code of aperture: DN

●Valve type code: Z-Gate valve J-Globe valve H-Check valve

●Driving manner code: 3-Worm gear worm 4-Spur gear 5-Bevel gear

6--Air driving 9-Electric driving(Hand wheel driving omitted)

●Connecting type code: 6-Welding 8--Bear and insert welding

●Design feature code: 0-Flexible wedge 2-Double gate

●Sealing formation code: H—13Cr Y—Stellite

●Pressure grade code: 1500Lb 2000Lb 2500Lb 3000Lb 3500Lb

●Body material code: C-WCB C1—WC1 I-WC6 V-WC9 C12--C12A

For example: 8"Z960Y1500LbC9

Note: 8"-15ooLb welded-end electric gate valve (manually actuation's code is omitted), the sealing face material of elastic wedge disc Stellite, body material Wc9.

1. Actuation modes: manual, electric, spur and bevel gear, pneumatic actuations, please make it clear at order.

2. Weld-connected gate valve and stop valve are suitable for the pipeline of PN1.6~32.0Mpa, P54/10oV-P57/170V, a working temperature <540C (570C for P57/170v) in various systems of petroleum, chemical industry, steam power, hydraulic etc. to cut off and get through the medium. The suitable media are: water, steam, oil goods, acid media and so on.

3. Conforms with the requirements of the domestic and foreign advanced standards. The middle cavity of the valve uses the pressure self-tightening sealing structure, the two ends of the branch pipe use welded structure and the welded groove can be connected per either the standard or the required one by users. Of a reliable seal, good performance and nice modeling.

4. The sealing faces of both disc and seat ring are made by means of built-up welding with either iron-based alloy or Stellite Co-based carbide alloy upon different requirements, wearable, high temperature resisting, corrosion resisting, good friction resisting and long duration.

5. The stem, after the modified and surface nitriding treatment, has a good friction and corrosion resistance and a back-seal structure to ensure the valve no leak outward from the stem when opened during running and able to replace the stem packing.

6. The valves with a large or a middle apertures can use the internal by-pass structure and be set with a rolling bearing and a thrust bearing, resulting in flexible open-close.

7. The electric stop valve is fitted with SMC valve electric actuator, features a small casing, light weight, full functions and a nice loutlook and can be used either with a program controlled computer or an electric actuator upon the user requirement.

| Serial models | Gate valve | Z60Y、Z560Y、Z960Y | ||||

| Globe valve | J61Y、J561Y、J961Y、J65Y、J565Y、J965Y、 | |||||

| Check valve | H64Y | |||||

| Pressure graderange | Class 1500~3500 | |||||

| Drift diameter range | 2¹ᐟ²"~22" | |||||

| Driving manner & scope of application | Gate valve | Hand wheel driving | Class 1500 | Class 2000~2500 | Class 3500 | |

| 2¹ᐟ²"~8" | 2¹ᐟ²"~6" | 3"~4" | ||||

| Bevel gear | Class 1500 | Class 2000~2500 | Class 3500 | |||

| 8"~22" | 6"~16" | 5"~12" | ||||

| Electric driving | Class 1500 | Class 2000~2500 | Class 3000 | Class 3500 | ||

| 2¹ᐟ²"~22" | 2¹ᐟ²"~16" | 10"~22" | 3"~18" | |||

| Globe valve | Hand wheel driving | Class 1500 | Class 2000~2500 | Class 3500 | ||

| 2¹ᐟ²"~6" | 2"~4" | 2¹ᐟ²"~3" | ||||

| Bevel gear | Class1500 | Class 2000~2500 | Class 3500 | |||

| 5"~8" | 4"~12" | 3"~6" | ||||

| Electric driving | Class 1500 | Class 2000~3500 | ||||

| 3"~8" | 2¹ᐟ²"~6" | |||||

| Y type globe valve | Hand wheel driving | Class 1500 | Class 2500 | |||

| 2¹ᐟ²"~6" | 2"~4" | |||||

| Bevel gear | Class 1500 | Class 2000 | Class 2500 | Class 3500 | ||

| 5"~8" | 4"~12" | 3"~14" | 3"~6" | |||

| Electric driving | Class 1500 | Class 1500 | Class 2500 | Class 3500 | ||

| 3"~8" | 4"~12" | 2"~14" | 3"~6" | |||

| Check valve | - | Class 1500 | Class 2500 | |||

| 2¹ᐟ²"~6" | 3"~8" | |||||

| Pressure class | Material | Shell test (MPa) | Seat test & back seat test (MPa) | Working pressure (MPa) | Working temperature (℃) |

| 1500Lb | WCB | 39.20 | 28.60 | 26.00/14.50 | -30~427 |

| WC1 | 36.70 | 26.85 | 24.40/17.10 | -30~454 | |

| WC6 | 39.50 | 8.20 | 26.40/6.30 | -30~552 | |

| WC9 | 39.60 | 10.10 | 26.40/6.55 | -30~570 | |

| 2000Lb | WCB | 52.20 | 38.15 | 34.70/19 | -30~427 |

| WC1 | 48.90 | 35.75 | 32.50/22.80 | -30~454 | |

| WC6 | 52.80 | 11.00 | 35.20/8.45 | -30~552 | |

| WC9 | 52.80 | 13.60 | 35.20/8.70 | -30~570 | |

| 2500Lb | WCB | 65.20 | 47.75 | 43.40/24.10 | -30~427 |

| WC1 | 61.20 | 44.75 | 40.70/28.50 | -30~454 | |

| WC6 | 65.90 | 13.80 | 43.90/10.60 | -30~552 | |

| WC9 | 65.90 | 16.92 | 43.90/10.60 | -30~570 | |

| 3000Lb | WCB | 78.20* | 57.30 | 52.10/28.90 | -30~427 |

| WC1 | 73.40* | 53.80 | 48.90/34.30 | -30~454 | |

| WC6 | 79.10* | 16.50 | 48.90/13.00 | -30~552 | |

| WC9 | 79.10* | 20.30 | 52.70/13.10 | -30~570 | |

| 3500Lb | WCB | 91.20* | 66.75 | 60.70/33.70 | -30~427 |

| WC1 | 85.50* | 62.70 | 57.00/40.00 | -30~454 | |

| WC6 | 92.30* | 19.30 | 61.50/14.80 | -30~552 | |

| WC9 | 92.30* | 23.65 | 61.50/15.25 | -30~570 |

Note: the shell test pressure with "*" mark can be negotiated with user a and specified as 1.5 times design pressure.

| Model | Pressure class (MPa) |

Test Pressure (MPa) | Working pressure (MPa) |

Working temperature | Applicable medium | ||

| Shell test | Seat test | Back seat test | |||||

| Z960Y-250 J961Y-250 |

250 | 37.5 | 27.5 | 27.5 | 14.5 | 427℃ | Water, steam |

| Z960Y-320 J961Y-320 |

320 | 48.0 | 35.2 | 35.2 | 12.5 | 427℃ | |

| Z960Y-P₅₄100 | P₅₄100 | 30.0 | 11.0 | 11.0 | 10.0 | 540℃ | Steam |

| Z960Y-P₅₄170V J961Y-P₅₄170V |

P₅₄170 | 48.0 | 18.7 | 18.7 | 17.0 | 540℃ | |

| Serial models | Gate valve | Z60Y、Z560Y、Z960Y | ||||

| Globe valve | J61Y、J561Y、J961Y、J65Y、J565Y、J965Y、 | |||||

| Check valve | H64Y | |||||

| Pressure grade range | 25.0MPa、32.0MPa、P₅₄100、P₅₄170 | |||||

| Drift diameter range | DN10~350mm | |||||

| Driving manner & scope of application | Gate valve | Electric driving | 25.0MPa | 32.0MPa | P₅₄100 | P₅₄170 |

| DN100~300mm | DN100~250mm | DN175~250mm | DN175~350mm | |||

| Globe valve | Hand wheel driving Electric driving | 25.0MPa、32.0MPa、P₅₄100、P₅₄140、P₅₄170 | ||||

| DN10~100mm | ||||||

| Design standard | JB/T 3595 | |

| Structural length | Welded connection | JB/T 2766、GB/T15188.1 |

| Pressure and temperature | JB/T 3595、JB/T 74 | |

| Test& inspection | JB/T 3595 | |

| Weld the slope mouth | JB/T 3595 | |

Note: valve connecting flange and welded groove can be designed and made upon the user requirements.

| Design standard | JB/T 3595 | |

| Structural length | Welded connection | JB/T 2766、GB/T15188.1 |

| Pressure and temperature | JB/T 3595 | |

| Test& inspection | JB/T 3595 | |

| Weld the slope mouth | JB/T 3595 | |

Note: valve connecting flange and welded groove can be designed and made upon the user requirements.

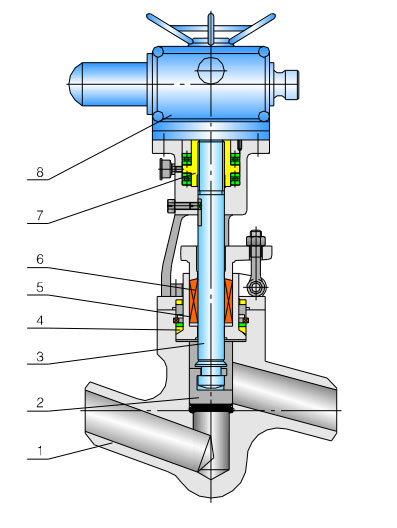

| No. | Part name | Material |  |

| 1 | Body | WCB、WC1、WC6、WC9、C12 | |

| 2 | Disc | 25、12Cr1MoVA、1Cr13 | |

| 3 | Stem | 1Cr17Ni12、2Cr13、20Cr1Mo1VA、25Cr2MoV | |

| 4 | Sealing ring | Graphite | |

| 5 | Bonnet | WCB、WC1、WC6、WC9、C12 | |

| 6 | Packing | Graphite | |

| 7 | Valve stem nut | Copper alloy | |

| 8 | Electronic device | Package |

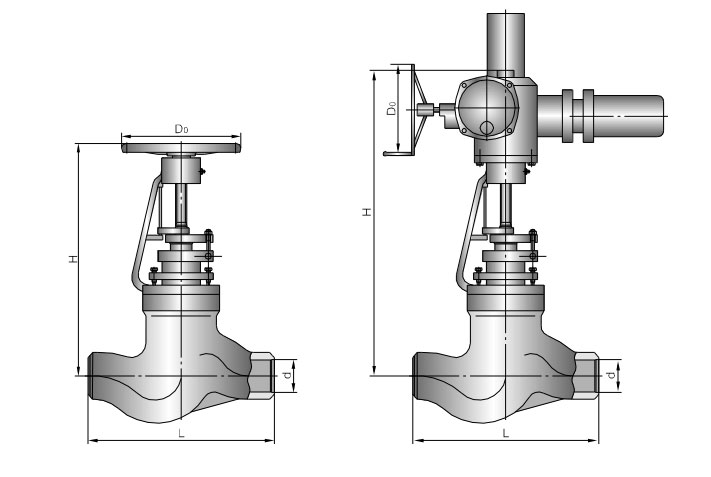

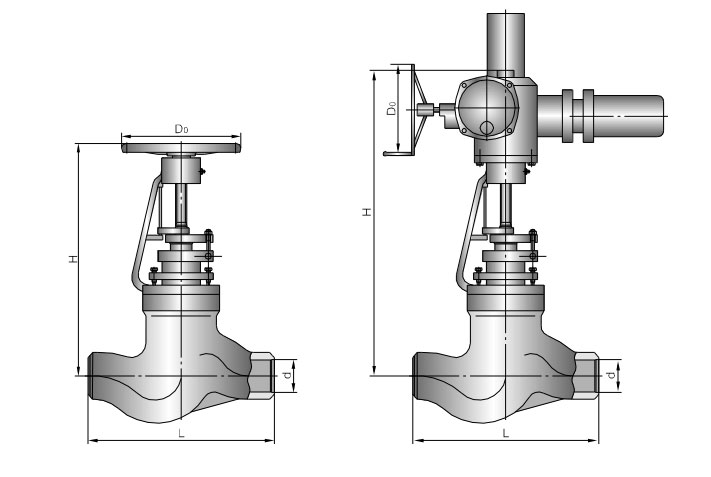

Model: J61Y-250、J961Y-250

| DN (mm) |

L | d | Hand-operated | Electric driving device | Electric driving device | ||||

| H | D₀ | Weight (kg) | Hand-operated | D₀ | Weight (kg) | ||||

| 10 | 120 | 10 | 210 | 10 | 8 | - | - | - | - |

| 20 | 170 | 19 | 272 | 20 | 10 | 600 | 250 | 72.5 | DZW10 |

| 25 | 1780 | 22 | 308 | 25 | 11.2 | 590 | 250 | 73 | DZW10 |

| 32 | 170 | 26 | 308 | 32 | 11.8 | 600 | 250 | 73.5 | DZW10 |

| 40 | 250 | 36 | 493 | 40 | 36.3 | - | - | - | - |

| 50 | 250 | 42 | 493 | 50 | 36.3 | 736 | 250 | 85 | DZW30 |

| 65 | 340 | 56 | 775 | 65 | 120 | 1060 | 450 | 188 | DZW45 |

| 80 | 390 | 64 | 848 | 80 | 150 | 1280 | 560 | 275 | DZW90 |

| 100 | 480 | 84 | 910 | 100 | 240 | 1290 | 560 | 310 | DZW90 |

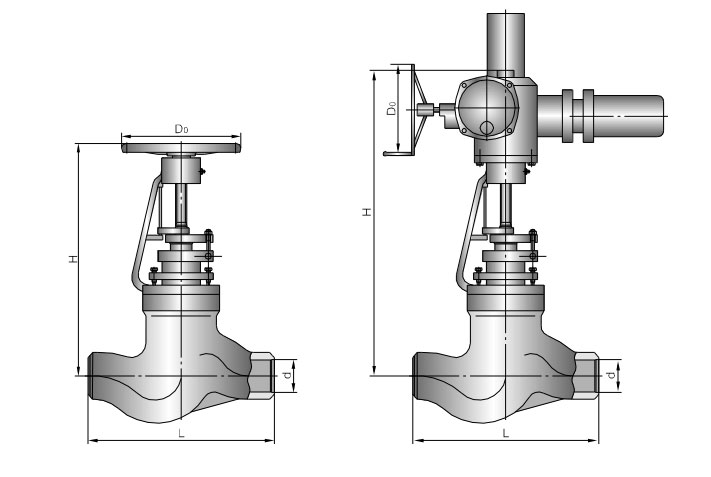

Model: J61Y-320、J961Y-320

| DN (mm) |

L | d | Hand-operated | Electric driving device | Electric driving device | ||||

| H | D₀ | Weight (kg) | Hand-operated | D₀ | Weight (kg) | ||||

| 10 | 120 | 10 | 210 | 160 | 8 | - | - | - | - |

| 20 | 170 | 19 | 272 | 180 | 10 | 600 | 250 | 72.5 | DZW10 |

| 25 | 170 | 22 | 308 | 240 | 11.2 | 590 | 250 | 73 | DZW10 |

| 32 | 170 | 26 | 308 | 240 | 11.8 | 600 | 250 | 73.5 | DZW10 |

| 40 | 250 | 36 | 493 | 320 | 36.3 | - | - | - | - |

| 50 | 250 | 42 | 493 | 320 | 36.3 | 736 | 250 | 85 | DZW30 |

| 65 | 470 | 60 | 895 | 560 | 200 | 1140 | 560 | 190 | DZW90 |

| 80 | 570 | 80 | 4085 | 700 | 280 | 1350 | 560 | 460 | DZW120 |

| 100 | 660 | 96 | 1045 | 700 | 340 | 1500 | 600 | 610 | DZW180 |

Model:J61Y-P₅₄170V、J961Y-P₅₄170V

| DN (mm) |

L | d | Hand-operated | Electric driving device | Electric driving device | ||||

| H | D₀ | Weight (kg) | Hand-operated | D₀ | Weight (kg) | ||||

| 10 | 120 | 10 | 210 | 160 | 8 | - | - | - | - |

| 20 | 170 | 19 | 272 | 180 | 10 | 600 | 250 | 72.5 | DZW10 |

| 25 | 170 | 22 | 308 | 240 | 11.2 | 590 | 250 | 73 | DZW10 |

| 32 | 170 | 26 | 308 | 240 | 11.8 | 600 | 250 | 73.5 | DZW10 |

| 40 | 250 | 36 | 493 | 320 | 36.3 | - | - | - | - |

| 50 | 250 | 42 | 493 | 320 | 36.3 | 736 | 250 | 85 | DZW30 |

| 65 | 762 | 60 | 895 | 610 | 500 | 1543 | 560 | 785 | DZW90 |

| 80 | 864 | 80 | 1315 | 900 | 750 | 1790 | 560 | 1089 | DZW120 |

| 100 | 965 | 88 | 1475 | 900 | 1000 | 1891 | 600 | 1451 | DZW180 |

The increasing popularity of IoT devices has driven the demand for industrial valves. The integration of IoT sensors in industrial valves enables real-time monitorin...

A gate valve is an opening and closing component, and its movement direction is perpendicular to the fluid direction. A gate valve can only be fully opened and fully...

Ball valve, the opening and closing element (ball) is driven by the valve stem and rotates around the axis of the ball valve. It can also be used for fluid regulatio...