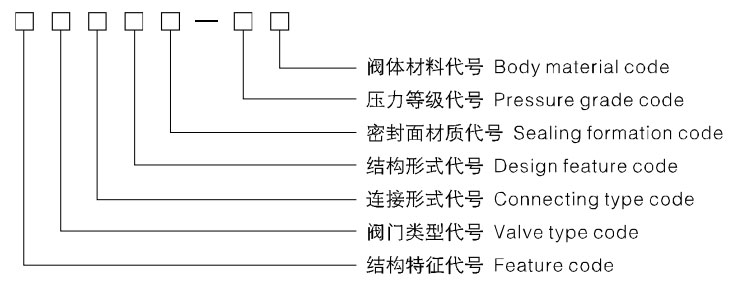

●Feature code: Bolt-jointed bonnet structure omitted Ps-Pressure sealed structure

●Valve type code: H-Check valve

●Connecting type code: 1-Interior whorl 2-Other whorl 4-Flange 6-Welding 7-To inserting 8-Bear and insert welding

●Design feature code:1-Lifting type 2-Lifting vertical type 4-Single-disc swing type 6--Dual-disc swing type

●Sealing formation code: Y—Hard alloy H—Alloy steel X-Rubber F-Polytetrafluoroethylene (PTFE)

●Pressure grade code: The 10 times of the nominal pressure MPa, pound grade io practical number

●Body material code: (1)Cast the valve body: C-WCB I-WC6、ZG1Cr5Mo V-WC9、ZG20CrMoV P-CF8、ZG1Cr18Ni9Ti

R-CF8M、ZG1Cr18Ni12Mo2Ti S-CF3 L-CF3M F-LCB N-LC3

(2)Forge thevalve body: C-A105 E-LF2 A-F11 V-F22 P-F304 R-F316 S-F304L L-F316L

Check valves are used in pipes under pressures between PN1.6~16.0MPa (Class150~250oLb), working temperatures -196~ 60℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features include:

1. The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2. Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3. Smallopening pressure, the disc can be opened fully with a very small pressure differential.

4. Inside-set bolt-bearing structure reduces leakage and reliable use.

5. PN>16.0Mpa (class15oo), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along with the pressure rise so as to ensure the sealing performance.

6. Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

| Serial models | (Ps)H44H(Y)、(Ps)H64H(Y)、(Ps)H41H(Y)、(Ps)H61H(Y)、(Ps)H42H(Y)、(Ps)H62H(Y) (Ps)H74H(Y)、(Ps)H71H(Y)、(Ps)H76H(Y)、(Ps)H72H(Y) |

| Pressure grade range | PN1.6~42.0MPa (Class150~2500) |

| Drift diameter range | DN15~1000mm (1/2"~40") |

| Pressure | Testing pressure at constant temperature (Mpa) | Applicable temperature | Applicable medium | ||

| The shell testing | Sealand test | ||||

| (MPa) Nominal rating pressure (PN) |

1.6 | 2.4 | 1.76 | -196~600℃ | Water,oil,steam,etc. |

| 2.5 | 3.75 | 2.75 | |||

| 4.0 | 6.0 | 4.4 | |||

| 6.4 | 9.6 | 7.04 | |||

| 10.0 | 15.0 | 11.0 | |||

| 16.0 | 24.0 | 17.6 | |||

| 25.0 | 37.5 | 27.5 | |||

| (Lb) Pound grade (Class) |

150 | 3.0 | 2.2 | ||

| 300 | 7.5 | 5.5 | |||

| 600 | 15.0 | 11.0 | |||

| 900 | 22.5 | 16.5 | |||

| 1500 | 37.5 | 27.5 | |||

| 2500 | 63.0 | 46.2 | |||

| Structural formation | Butt-clamped lifting vertical type check valve |

| Design standard | GB/T 12224 |

| Face to face | GB/T 15188.2 |

| Flanged ends | JB/T 79、GB/T9113、HG20592 |

| Test& inspection | JB/T9092 |

Notes: The sizes of valve connecting flange and butt-welding terminas can be designed according to customer's requirement.

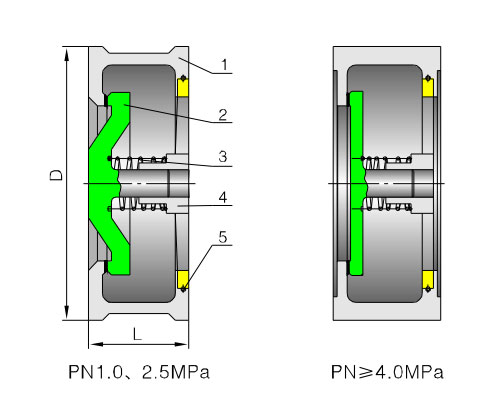

| No. | Part name | Material |

| 1 | Body | WCB、CF8、CF8M、CF8C、CF3、CF3M |

| 2 | Disc | WCB、CF8、CF8M、CF8C、CF3、CF3M |

| 3 | Spring | 4Cr13、60Si2Mn、1Cr18Ni9Ti、0Cr18Ni12Mo2Ti |

| 4 | Plate | WCB、CF8、CF8M、CF8C、CF3、CF3M |

| 5 | Lock ring | 4Cr13、60Si2Mn、1Cr18Ni9Ti、0Cr18Ni12Mo2Ti |

Model: H72H、H72Y

| PN (MPa) |

DN (mm) |

Dimensions (mm) | Weight (kg) |

PN (MPa) |

DN (mm) |

Dimensions (mm) | Weight (kg) |

PN (MPa) |

DN (mm) |

Dimensions (mm) | Weight (kg) |

|||

| L | D | L | D | L | D | |||||||||

| 1.0 1.6 |

15 | 16 | 53 | 0.15 | 2.5 | 15 | 16 | 53 | 0.2 | 4.0 | 15 | 25 | 63 | 0.3 |

| 20 | 19 | 63 | 0.25 | 20 | 19 | 63 | 0.3 | 20 | 31.5 | 74 | 0.4 | |||

| 25 | 22 | 73 | 0.4 | 25 | 22 | 73 | 0.45 | 25 | 35.5 | 84 | 0.6 | |||

| 32 | 28 | 84 | 0.55 | 32 | 28 | 84 | 0.6 | 32 | 40 | 90 | 1.0 | |||

| 40 | 31.5 | 94 | 0.75 | 40 | 31.5 | 94 | 0.8 | 40 | 45 | 105 | 1.5 | |||

| 50 | 40 | 109 | 1.2 | 50 | 40 | 109 | 1.2 | 50 | 56 | 115 | 2.0 | |||

| 65 | 46 | 129 | 2.0 | 65 | 46 | 129 | 2.3 | 65 | 63 | 140 | 3.2 | |||

| 80 | 50 | 144 | 2.6 | 80 | 50 | 144 | 3.0 | 80 | 71 | 150 | 7.2 | |||

| 100 | 60 | 164 | 5.7 | 100 | 60 | 170 | 7.0 | 100 | 80 | 177 | 11 | |||

| 125 | 90 | 194 | 10 | 125 | 90 | 197 | 12 | 125 | 110 | 213 | 18 | |||

| 150 | 106 | 220 | 13 | 150 | 106 | 220 | 13 | 150 | 125 | 250 | 22 | |||

| Structural formation | Butt-clamped lifting vertical type check valve |

| Design standard | GB/T 12224 |

| Face to face | GB/T 15188.2 |

| Flanged ends | JB/T 79、GB/T9113、HG20592 |

| Test& inspection | JB/T9092 |

Notes: The sizes of valve connecting flange and butt-welding terminas can be designed according to customer's requirement.

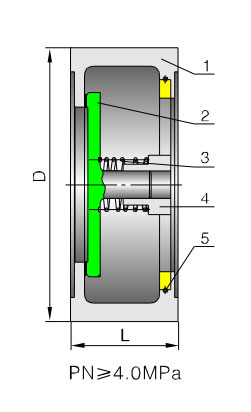

| No. | Part name | Material |

| 1 | Body | WCB、CF8、CF8M、CF8C、CF3、CF3M |

| 2 | Disc | WCB、CF8、CF8M、CF8C、CF3、CF3M |

| 3 | Spring | 4Cr13、60Si2Mn、1Cr18Ni9Ti、0Cr18Ni12Mo2Ti |

| 4 | Plate | WCB、CF8、CF8M、CF8C、CF3、CF3M |

| 5 | Lock ring | 4Cr13、60Si2Mn、1Cr18Ni9Ti、0Cr18Ni12Mo2Ti |

Model: H72H、H72Y

| PN (MPa) |

DN (mm) |

Dimensions (mm) | Weight (kg) |

PN (MPa) |

DN (mm) |

Dimensions (mm) | Weight (kg) |

PN (MPa) |

DN (mm) |

Dimensions (mm) | Weight (kg) |

|||

| L | D | L | D | L | D | |||||||||

| 6.4 | 15 | 25 | 63 | 0.3 | 10.0 | 15 | 25 | 63 | 0.3 | 16.0 | 15 | 25 | 59 | 0.3 |

| 20 | 31.5 | 74 | 0.4 | 20 | 31.5 | 74 | 0.4 | 20 | 31.5 | 70 | 0.4 | |||

| 25 | 35.5 | 84 | 0.6 | 25 | 35.5 | 84 | 0.6 | 25 | 35.5 | 80 | 0.6 | |||

| 32 | 40 | 90 | 1.0 | 32 | 40 | 90 | 1 | 32 | 40 | 93 | 1.0 | |||

| 40 | 45 | 105 | 1.5 | 40 | 45 | 105 | 1.5 | 40 | 45 | 101 | 1.5 | |||

| 50 | 56 | 115 | 2.0 | 50 | 56 | 122 | 2.2 | 50 | 56 | 143 | 2.2 | |||

| 65 | 63 | 140 | 3.2 | 65 | 63 | 147 | 3.5 | 65 | 63 | 163 | 3.5 | |||

| 80 | 71 | 150 | 7.2 | 80 | 71 | 157 | 7.5 | 80 | 71 | 178 | 7.5 | |||

| 100 | 80 | 177 | 11 | 100 | 80 | 183 | 12 | 100 | 80 | 210 | 12 | |||

| 125 | 110 | 213 | 18 | 125 | 110 | 220 | 18 | 125 | 110 | 249 | 19 | |||

| 150 | 125 | 250 | 22 | 150 | 125 | 260 | 24 | 150 | 125 | 282 | 24 | |||

| Structural formation | Butt-clamped lifting vertical type check valve |

| Design standard | API 594 |

| Face to face | ASME B16.10 |

| Flanged ends | ASME B16.5 |

| Test& inspection | API 598 |

Notes: The sizes of valve connecting flange and butt-welding terminas can be designed according to customer's requirement.

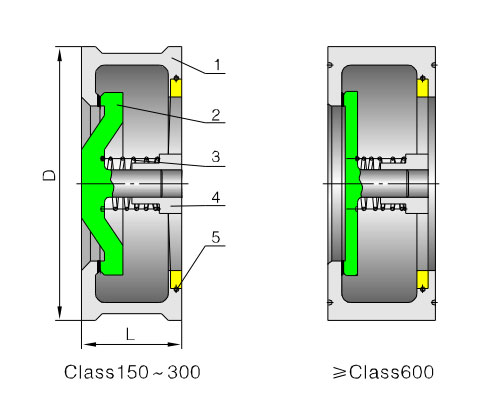

| No. | Part name | Material |

| 1 | Body | ASTM A216-WCB、ASTM A351-CF8、CF8M、CF8C、CF3、CF3M |

| 2 | Disc | ASTM A216-WCB、ASTM A351-CF8、CF8M、CF8C、CF3、CF3M |

| 3 | Spring | AISI9260、AISI6150、ASTM A182-F304、F316、F321、F304L、F316L |

| 4 | Plate | ASTM A216-WCB、ASTM A351-CF8、CF8M、CF8C、CF3、CF3M |

| 5 | Lock ring | AISI 9260、AISI 6150、ASTM A 182-F304、F316、F321、F304L、F316L |

Model: H72H、H72Y

| Class | 150 | 300 | 600 | 900 | |||||||||

| PN (MPa) |

NPS (in) |

Dimensions (mm) | Weight (kg) |

Dimensions (mm) | Weight (kg) |

Dimensions (mm) | Weight (kg) |

Dimensions (mm) | Weight (kg) |

||||

| L | D | L | D | L | D | L | D | ||||||

| 15 | ¹/₂ | 16 | 47 | 0.2 | 25 | 53 | 0.23 | 25 | 53 | 0.25 | 25 | 63 | 0.3 |

| 20 | ³/₄ | 19 | 57 | 0.3 | 31.5 | 65 | 0.36 | 31.5 | 65 | 0.38 | 31.5 | 69 | 0.4 |

| 25 | 1 | 22 | 66 | 0.45 | 35.5 | 72 | 0.52 | 35.5 | 72 | 0.55 | 35.5 | 78 | 0.6 |

| 32 | 1 ¹/₄ | 28 | 75 | 0.6 | 40 | 81 | 0.75 | 40 | 81 | 0.8 | 40 | 88 | 1.0 |

| 40 | 1 ¹/₂ | 31.5 | 85 | 0.8 | 45 | 95 | 1.1 | 45 | 95 | 1.2 | 45 | 98 | 1.5 |

| 50 | 2 | 40 | 103 | 1.2 | 56 | 110 | 1.95 | 56 | 110 | 2.0 | 56 | 142 | 2.5 |

| 65 | 2 ¹/₂ | 46 | 122 | 2.3 | 63 | 129 | 2.9 | 63 | 129 | 2.0 | 63 | 164 | 4.0 |

| 80 | 3 | 50 | 135 | 3.0 | 71 | 148 | 5.5 | 71 | 148 | 6.0 | 71 | 167 | 8.0 |

| 100 | 4 | 60 | 173 | 7.0 | 80 | 180 | 9.0 | 80 | 192 | 10 | 80 | 205 | 13 |

| 125 | 5 | 90 | 196 | 12 | 110 | 215 | 15 | 110 | 240 | 17 | 110 | 247 | 20 |

| 150 | 6 | 106 | 222 | 15 | 125 | 250 | 20 | 125 | 265 | 22 | 125 | 288 | 25 |

The increasing popularity of IoT devices has driven the demand for industrial valves. The integration of IoT sensors in industrial valves enables real-time monitorin...

A gate valve is an opening and closing component, and its movement direction is perpendicular to the fluid direction. A gate valve can only be fully opened and fully...

Ball valve, the opening and closing element (ball) is driven by the valve stem and rotates around the axis of the ball valve. It can also be used for fluid regulatio...